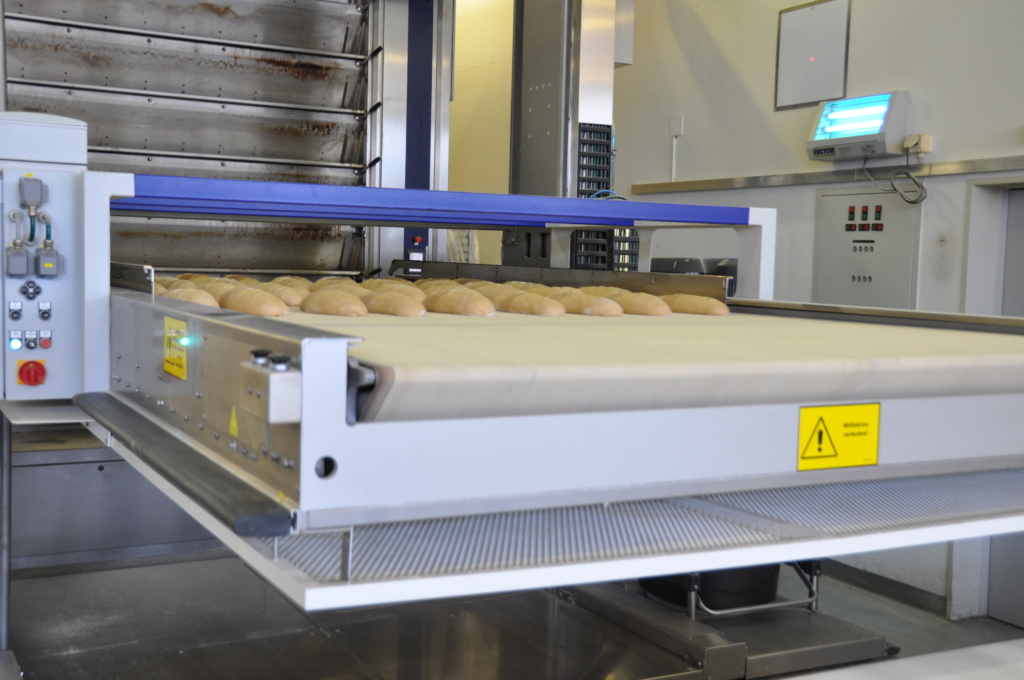

CONTI BAKE BE 6570

Bakery belt with woven plastic spiral splice or endless

It can be changed and installed within 10 minutes and can run over every knife edge and shaft diameter. Its air-permeable design means it is absolutely non-adhesive and is therefore suitable for all proofing systems. The bakery belt is approved for foodstuffs, is FDA certified and can withstand short-term temperatures of up to 240°C (for oven feeders)

We produce each belt individually for all dimensions (with woven in spiral splice) while keeping delivery times from Germany as short as possible

Details on technical data

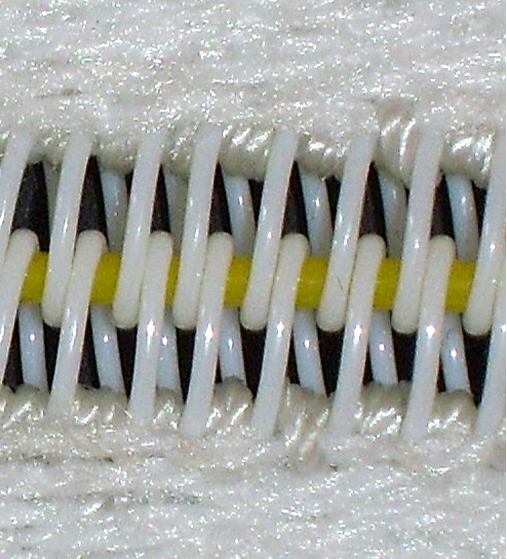

Construction of bearing side

100% polyester, multi-filament with felt-like surface, specially treated dough repelling surface (no sticking)

Air permeability: 1,000 m³/h with 10mm WS

Construction of running side

100% polyester, mono-filament

Friction coefficient: 0.15 on chrome steel

Colour

blue

Tear resistance

144 kg/cm belt width

Tensile strength

for 1% elongation - 5 kg / cm width

Belt thickness

2,2 mm

Weight

approx. 1,5 kg/m²

Temperature resistance

continuous up to 160°C, short-term

(max. 10 min) up to 240°C

with silicone impregnation: continuous up to 155°C, short-term (max. 10 min) up to 250°C

Knife edges

from Ø 6 mm

Belt widths

up to 4,100 mm without middle seam, thus very stable crosswise, good guidance capabilities, no re-tensioning

Applications

General use in industrial baking, anywhere dough is being transported: transfer belts, proofing belts, dough sheeter belts, positioner belts, oven loader / feeder, robot etc.

Chemical properties

Resistant to water, moisture, does not mould, washable, dough does not stick

VConnection / splice

systems developed by us:

- Completely endless - no connection / splice

- Spiral splice - the spirals are woven into the belt manually

- Suitable for all knife edges

References

This belt has proved successful in all bakery applications for 30 years

Special execution

- Impregnation using silicone - conforms to FDA

- coatings up to 4 mm with silicone